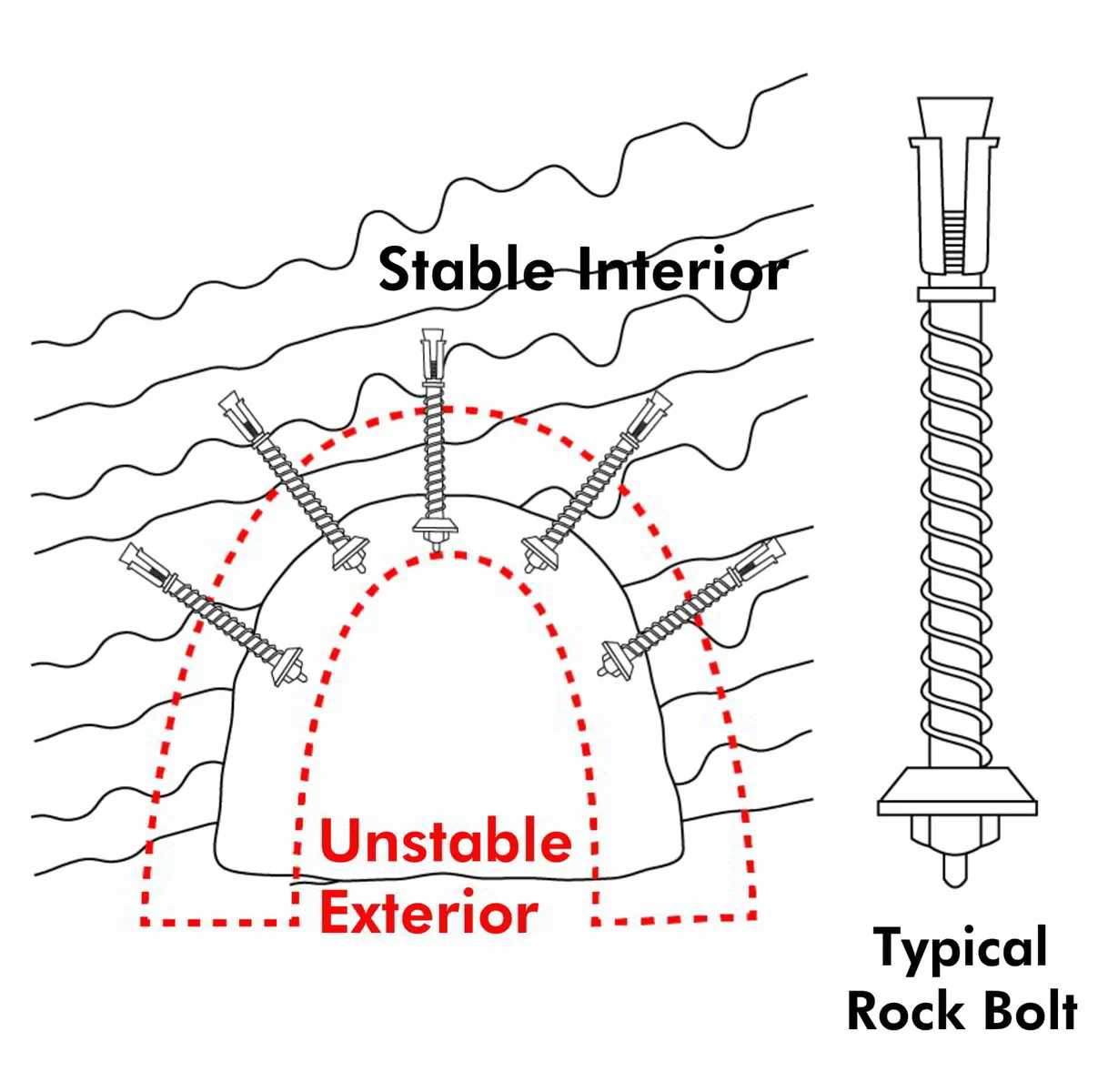

When it comes to deep underground mining and tunneling, rock bolts are often necessary for ensuring that the rock remains stable and safe during excavation.

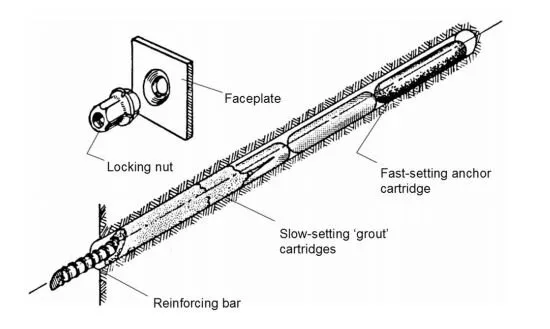

Bolting is the process of inserting a plain steel rod into a borehole in the strata to bear the load from the rock around the tunnel.

Though a temporary mining and tunnelling application doesn't require additional support components, a permanent application will need cement-like grouts or resins to fill gaps between the bolt and rock.

Cable Bolting

Cable bolting is another technique that offers additional support to the rock during mining and tunneling projects.

Cable bolts are long, grouted reinforcement tools that help support and stabilize the rock mass above the profile of a tunnel deep underground.

For years, the mining community would use resin cartridges to inject resins around bolting for rock reinforcement.

Though the process is effective, technological advancements have led to a recent creation: a pumpable resin system.

Though a pumpable resin system is new to the mining industry, it is quickly gaining popularity for its rock reinforcement abilities.

Resin cartridges and pumpable resins are reliable systems for cable and rock bolting reinforcement.

Consider the guide below to learn more about both approaches, their wide range of benefits, and drawbacks.

Underground Mining and Tunnelling Complications

The potential for safety problems increases significantly with deep underground mining and tunnelling.

When you drill deep into the earth, the rock above the mine experiences stress, affecting the stability of the strata.

Rock reinforcement is necessary, but it becomes more difficult underground.

Creating mines involves large-scale movements, which increases the potential for a collapse.

Rock reinforcement with cable or rock bolting with grout or resin becomes vital to the safety of the workers and technical equipment.

Though traditional long-term rock stability applications like sprayed concrete and rock bolts with cement-like grouts work well for standard mining operations, stability installations are complex in deep mines.

Installation becomes more of a challenge in poor ground.

Mining activity and geological structure contribute to poor or bad ground conditions, further increasing the stress of the mine's formation and the need for rock reinforcement.

A rock bolt installation in these conditions is certainly possible. Still, it may create significant quality concerns, increase installation times, and raise the potential for the mining cycle to develop a bottleneck.

Pumpable Resin System for Bolting

The idea of pumpable resins for rock bolting is not new, but the system was not available until recently. It took a few years for the chemical technology to catch up to the idea.

The purpose of pumpable resins is to combine the effectiveness of cement-like grout with the curing speed of resin.

It typically takes between 12 to 24 hours for cementitious grout to cure and harden around a rock bolt, during which mining professionals can't enter the mine. Resins, however, take a few minutes to set.

Regardless of a mine's ground conditions, a pumpable resin system is highly effective for anchoring rock bolts long-term.

Because resins are fluid in movement and solidify when motionless, it's possible to install resin around a bolt overhead without requiring additional borehole sealing.

Benefits of Pumpable Resin System

Quick Installation Cycles

Deep mining with bad ground conditions requires quick action when it comes to rock reinforcement.

For that reason, the new pumpable resins are systems in regular use in several major mine developments.

Cementitious grouting around a rock bolt takes up to 24 hours to solidify and stabilize the area.

Since work cannot resume in the mine until the curing ends, mine developments can quickly get off schedule.

Resin cartridges significantly reduce the installation time by taking up the load in 10 to 15 minutes.

However, a pumpable resin system and a self-drilling bolt can get the job done in three minutes or less.

Though both options offer quick cycle times, pumpable systems are preferred because they work for all ground conditions and rock quality.

Enhanced Mining Stability

Improved long-term rock stability is another benefit of this system. The resin penetrates even the most minor cracks around the bolt and borehole.

The improvement occurs because the resin quickly consolidates the ground.

Even if a borehole diameter is larger than expected, an operator can pump the resin until they fill the entire space.

Usable With Hollow and Cable Bolts

Pumpable resins have multiple applications. Besides installing them around a rock bolt, it's also possible to use pumpable resins with cable and hollow bolts or self-drilling anchors.

Self-drilling anchors are open in the center with a drill bit on the tip for creating boreholes.

The system works well in poor ground conditions, and the pumpable resin will take up the load in minutes, not hours.

Drawbacks of a Pumpable Resin System

Because the system is still relatively new to the underground mining industry, there aren't many disadvantages to using pumpable resins.

However, they do require some form of adaptability for workers and machines.

The market currently has some equipment available that includes a pumpable resin system within the rig.

The machinery can be expensive because the system is new and in demand. It is possible to retrofit old equipment to handle the system at a lower cost than a new machine.

Training is another must for pumpable resins. Mining operations will need to train workers to use the new equipment and understand the system's technical aspects. Some machine designs allow for quick learning and easy use.

Resin Cartridges

Like pumpable systems, resin cartridges help bolts bond to the surrounding rock, both above and within the ground.

The resin will anchor a bolt regardless of its size with a quick operation. It doesn't require injection equipment.

Cartridges consist of two parts surrounded by a thin plastic film. The first component is polyester resin grout, and the second component is the cartridge's catalyst.

The cartridge resembles the shape of a tube or long sausage with clipped ends.

After a drill makes a hole, the cartridge goes inside. When a rotating rock bolt or bar pushes through the cartridge, the two components mix to initiate a curing process.

After the mix cures, it's usually more rigid than the surrounding rock. Cartridges are a quick, economical way to anchor a bolt.

Benefits of Resin Cartridges

Usable for All Ground Conditions

A bolt installation can be more difficult under bad ground conditions, but it isn't impossible.

As long as the borehole is stable, operatives can install a cartridge to form long-lasting grouting.

Simple Installation Cycle

The bolting system works for placing a bolt in any position or angle in the mine or tunnel ceiling. After creating holes, the cartridges are injected into them.

To initiate an immediate stabilizing chemical reaction, simply insert a bolt and rotate it to mix the components inside the cartridge.

Reliable Bonding Capacity

A thin plastic film separates the grouting resin from its catalyst material. When the two components mix within the hole, they create an intense mechanical interlock with the bolt and surrounding rock.

It takes minutes for the mixture to cure, forming a reliable bond to the surrounding rock with heavy loading capabilities.

The measurements of the resin and its catalyst are carefully calculated. The chemical nature of the compounds and their quantity allow for quick mixing while reducing how much resin pours out of the hole.

Drawbacks of Resin Cartridges

A rock bolt grouted with a cartridge is a popular way to reinforce bolts in underground mines because it has a faster installation cycle than traditional reinforcement methods.

However, unstable ground conditions can make it tricky to install the cartridge in a hole.

The cartridge must go in the hole before rock bolting can occur, and the bolt will rotate to combine the resin.

If the ground is too loose, the hole could collapse after removing the drill bit, making the cartridge installation more difficult, if not impossible.

An overbreak around the hole could also affect how much resin makes it into the hole.

A grouted resin cartridge holds specific amounts of material, requiring precise hole measurements.

Even minute shifts in or around the borehole could need more resin than the cartridge contains to properly seal the rock bolt, significantly reducing the load the bolt could hold.

Conclusion

Pumpable resins are relatively new, but the system shows exceptional promise with how fast it stabilizes the area around a bolt.

The system provides immediate, long-term results with a broad range of benefits and few drawbacks.

When combined with a self-drilling anchor, the system allows bolting to take a load after a simple installation process.

A resin cartridge system also provides immediate results around bolting in comparison to traditional reinforcement methods.

Installation is simple, fast, and operators can insert a cartridge in holes regardless of its position.

Pumpable resins and grouted resin cartridges offer a wide range of advantages over traditional rock reinforcement techniques for mining and tunnelling operations.

Working in deep mines presents distinct challenges regarding safe practices because the ground conditions can become unstable, which may affect everything from reliable reinforcement tactics to operation scheduling.

Resin systems and bolting provide fast, long-term stability solutions.

So, what's next?

Stay tuned to this blog and our Facebook group to learn more about mining.

Our Facebook group, An Underground Miner, is a funny and informative group of miners and mining enthusiasts.

To be part of our ongoing conversation, all you have to do is join our group today!

This article was written by An Underground Miner