Tunnel construction plays an important role in creating passageways for mines or routes for transportation.

However, excavating an underground tunnel can lead to dangerous situations when done incorrectly.

Thorough and well-planned tunnel construction methods mean tunnels won't be mined in unstable material, leading to their collapse.

In this beginner's guide, we'll go over what an underground tunnel is, how they're built, and more. Let's get started!

⛏️ What is an Underground Tunnel?

A tunnel is an underground passageway that's enclosed except for the entryway and exit. It's dug through surrounding soil, earth, or rock.

These structures create underground space, whether for storage purposes, as a passage underneath an obstruction like a mountain or hill, or to access natural resources.

⛏️ How is an Underground Tunnel Built?

Creating an underground tunnel is a marvel of engineering that involves meticulous planning and execution.

Here's an in-depth look at how these subterranean passages are constructed:

Initial Groundwork and Design:

Before any physical work begins, engineers conduct thorough geological surveys to understand the ground conditions.

This phase determines the feasibility of the tunnel and the best construction method to employ.

Trenching and Excavation:

For some tunnels, like cut and cover tunnels, the process starts with trenching.

A trench is carefully excavated to the required depth, with temporary ground support installed to prevent collapses.

This method is particularly common in urban areas where the tunnel depth is relatively shallow.

Tunnel Boring Machine (TBM) Method:

For deeper or longer tunnels, a TBM is often the tool of choice.

This massive machine grinds through the earth and rock with a rotating cutting head, simultaneously installing concrete lining segments to support the tunnel walls.

The TBM's precision and efficiency make it ideal for creating smooth-walled tunnels with minimal disruption to the surrounding environment.

Drilling and Blasting:

In more traditional methods, controlled explosions are used to break up the rock.

This is followed by the removal of debris and the installation of support structures.

While this method can be more disruptive and less predictable than using a TBM, it is sometimes necessary in conditions where a TBM cannot operate effectively.

Ground Support Installation:

As the tunnel progresses, various forms of ground support are installed. This can include steel arches, rock bolts, and shotcrete—a sprayable concrete—to reinforce the tunnel interior and ensure stability.

Secondary Lining and Infrastructure:

Once the primary support is in place, a secondary lining of concrete may be added for additional strength and to create a smooth, finished surface.

This phase also includes the installation of necessary infrastructure, such as lighting, ventilation, and emergency exits.

Waterproofing and Insulation:

To protect against water ingress and to manage temperature variations, tunnels are often waterproofed and insulated. This is crucial for maintaining structural integrity and for the comfort and safety of users.

Final Touches:

The last step involves the installation of roadbeds, tracks, or other surfaces depending on the tunnel's purpose, as well as the final testing of all installed systems to ensure operational safety.

Throughout the construction process, continuous monitoring is essential to detect any movement or instability in the tunnel structure.

Advanced technologies, such as laser scanning and ground-penetrating radar, are used to maintain the highest safety standards.

The construction of an underground tunnel is a complex interplay of geology, engineering, and technology, requiring a diverse team of specialists to bring these crucial passageways to life.

⛏️ How Do Underground Tunnels Not Collapse?

There's a lot of planning that goes into underground tunnel construction.

The surface conditions are a good starting point - will the tunnel be built on soft ground or hard, sound rock?

The answer will determine the technique that must be used.

Engineers must consider the pressure exerted by overlying materials when constructing underground tunnels.

This pressure, akin to atmospheric pressure, results from the weight of the soil and rock layers above.

As one delves deeper beneath the Earth's surface, the pressure increases due to the cumulative weight of these layers.

This geostatic pressure can significantly compress the subsurface materials, influencing the stability and structural integrity of the tunnel.

It is essential to account for this pressure gradient in tunnel design to ensure adequate support and prevent collapse.

With this in mind, when a horizontal passageway is built through this material, you interrupt the flow of these compressive forces.

Think of it this way - if you remove a column from a building, you weaken the structure.

When excavating a passageway, you're removing support from the material above.

Therefore, when building a tunnel, it's essential to replace this support.

Common ways to achieve this include lining the tunnel with steel or concrete. This provides support to the tunnel walls.

These passageways use strong materials like concrete, steel, or iron.

They must carry the weight of people and vehicles traveling through them.

Engineers will also add extra support to more extensive tunnels for better stability.

Metal rock bolts in conjunction with resin are used to secure tunnels, and there's drilling done underneath rocks to prevent collapses.

This process is very costly but integral to ground support and overall safety.

⛏️ Do Tunnels Ever Collapse?

Like any structure built by man, there's a risk of collapse.

However, many measures are put in place to prevent tunnels from collapsing from the initial support to the final liner support. This makes collapsing highly unlikely.

Causes of collapse may include floods, earthquakes, or corroding infrastructure.

For instance, water leaking into the vertical shaft will cause the excavation to become unstable. This increases the risk of collapse.

⛏️ Ancient Tunneling

Tunnels have been used for years to mine ores, carry coal, conduct water and sewage, among other uses.

Underground chambers were often used to connect passageways. They continue to be used for power plants, pumping stations, storage of oil, and more.

Ancient tunnels were likely constructed by prehistoric people that wanted to make their caves bigger.

All major ancient civilizations had their own methods of building beneath the surface.

For instance, in Babylonia, they were used for irrigation. Around 2180 BC, pedestrian tunnels were built under the Euphrates River to connect the royal palace with the temple.

Brick tunnel lining was used to create this 3,000 feet long tunnel. This type of tunneling was achieved by diverting the river during the dry season.

Egyptian techniques included cutting soft rocks with copper saws or hollow reed drills surrounded by an abrasive.

This technique was first used for quarrying stone blocks and later to excavate temple rooms within rock cliffs.

Eventually, very elaborate temples were being excavated within solid rock in India and Ethiopia.

⛏️ Modern Tunnel Construction

It's interesting to learn how construction for tunnels has evolved from ancient times to the Middle Ages and into the present day.

From soft soil to hard rock, tunnels are dug in different materials.

Tunneling methods depend on several factors such as surface conditions, length of the tunnel drive, tunnel depth, and more.

Three main methods of building tunnels include cut-and-cover, bored, and immersed tunnels.

Cut and Cover

Cut-and-cover tunnels are excavated in a shallow trench.

The overhead support needs to be strong enough to hold the load of what will be built above the tunnel, for example, buildings.

Cut-and-cover tunneling includes two methods:

- Bottom-up method. For this technique, a trench is excavated, and the tunnel is constructed within it. It can be held in place by varying materials like concrete, precast arches, or corrugated steel arches. In ancient times, brickwork was used.

- Top-down method. For this method, the side support walls and the capping beams are built from the ground level. The tunnel roof is then constructed using precast beams or concrete. The surface is then placed back on except for access openings.

Bored

Bored tunnels are made in situ (in position) without removing the ground surface.

This is possible through trenchless technologies like the New Austrian Tunnel Method (NATM), pipe jacking or microtunnelling.

A tunnel boring machine or TBM is used to automate the tunneling process.

Thanks to underground space technology like TBMs, tunneling costs can be reduced significantly.

The downfall of this construction method is the large size of tunnel boring machines.

It's often difficult to transport a TBM to the site of construction. It's also very expensive to assemble the TBM on-site.

There are many TBM designs for operation in a variety of conditions (hard rock, soft ground, etc.).

Some types even have pressurized compartments at the front that allow them to be used in water conditions below the water table. This helps pressurize the ground and balance the water pressure.

TBMs are the preferred method nowadays over older tunneling methods. The old method of tunneling in compressed air required operators to work under high pressure and undergo decompression procedures after their shifts.

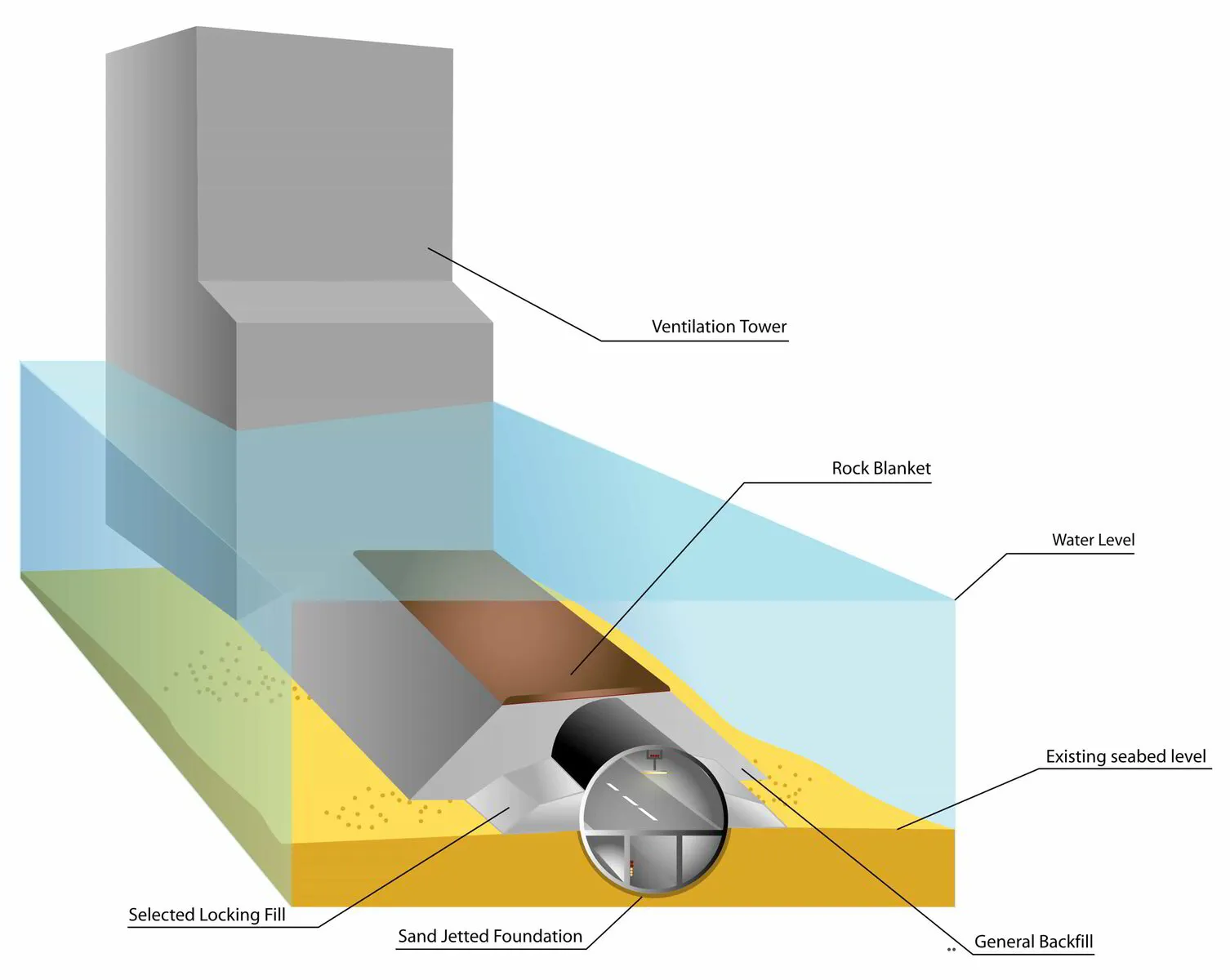

Immersed

For this type, a tube is sunk into a body of water. This method consists of concrete-filled steel elements that are constructed underwater.

These segments are constructed in one place and then floated to the tunnel site, where they're sunk into place.

They're then linked together using underground construction technology.

🙋 Does this construction method use deep tunnels or shallow tunnels?

Cut-and-cover and immersed-tube tunnels usually include shallow tunnels.

⛏️ Frequently Asked Questions

What is a tunnel roof?

This refers to the top of the tunnel and is an integral part of underground construction.

What is a pilot tunnel?

Also known as a pilot drift, this is a small tunnel excavated over part of a larger tunnel. They're made to explore ground conditions or assist in the final excavation.

What are three common types of tunnels?

The most common types of tunnels include cut-and-cover, bored, and immersed.

What is the meaning of tunneling method?

This refers to the method used to construct an underground space. An underground space can be achieved through several different methods. The right one depends on several factors, like the tunnel's intended use or the surface conditions (soft soil, hard rock, etc.).

What's the best school for miners?

The best school for mining engineering is the Colorado School of Mines. Highly ranked as the best school for mining, this establishment is dedicated to mentoring students in lasting change in areas related to the Earth.

⛏️ Browse An Underground Miner For More Articles

Underground tunnels are used for many purposes, from storage to transportation to accessing natural resources.

This mining method continues to be a popular and effective way to mine natural resources like coal, iron, or gold.

To learn more about mining methods, be sure to check out our blog!

This article was written by An Underground Miner