Placer mining is a way to separate various mining materials.

Placer mining differs from other methods and mining operations like hardrock mining.

For example, people use hardrock mining to extract the veins of sought-after materials from solid rocks.

However, placer miners use placer mining to separate materials like gold from hard gravel or sand.

The Definition of Placer Mining

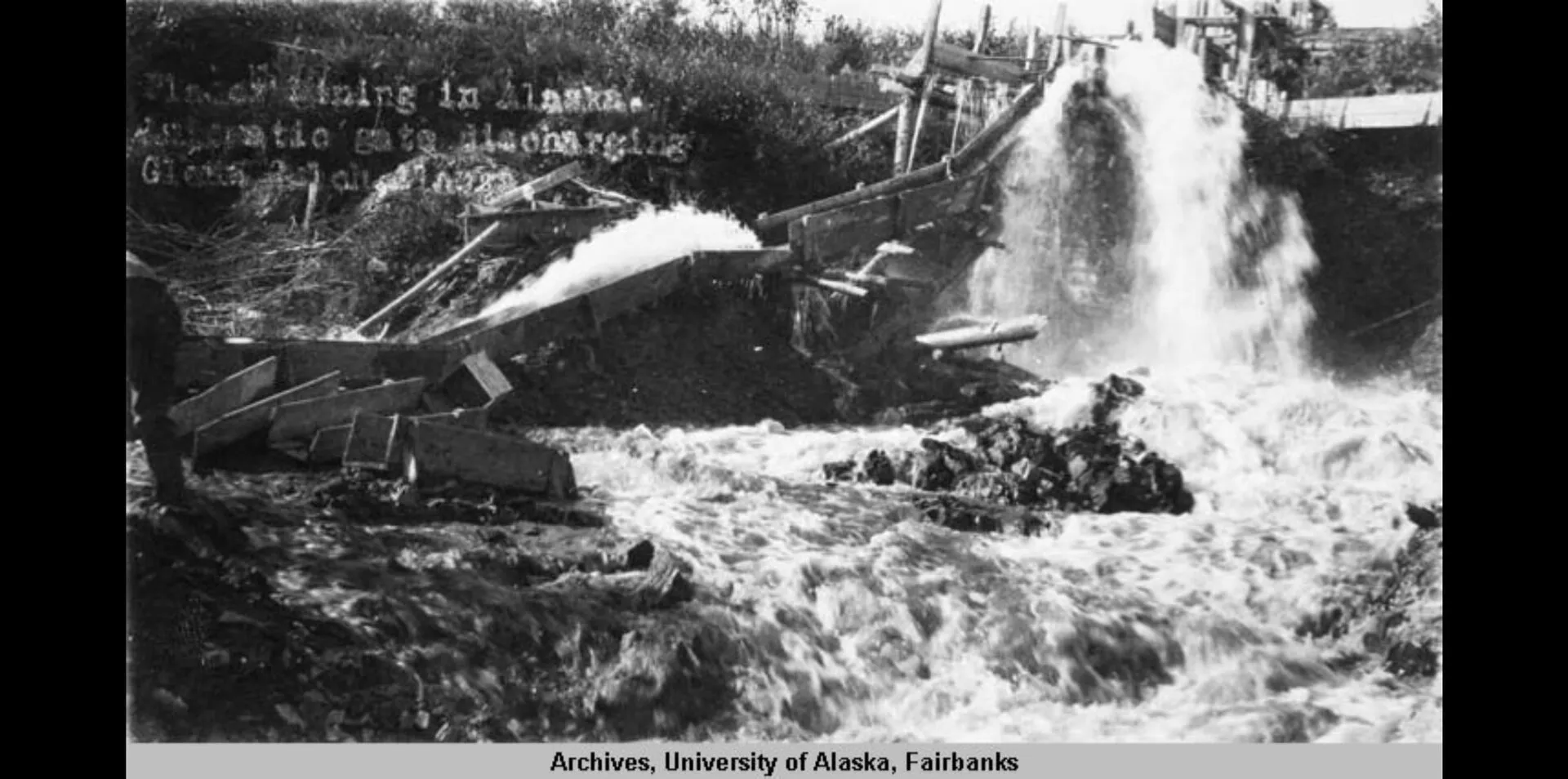

Image: UAF, George and Louise Lockyear Papers

Separating heavy minerals from gold-rich gravel, sand, or hard rock is the simplest placer mining definition.

The word placer itself is thought to originate from Spanish and Catalan and means "sand bar" or "shoal".

The word entered people's vocabulary in North America during the California Gold Rush in 1848.

Placer Gold Mining Prior History

Before major gold placer mining events such as the California Gold Rush and the Klondike Gold Rush, placer mining was responsible for supplying much of the ancient world with fine gold.

Romans used hydraulic mining techniques like hushing to uncover precious minerals like gold.

These mining methods were prevalent in northern Spain following Augustus's conquest in 25 BC.

An extensive site during this time was the Las Médulas, consisting of seven aqueducts 30 miles long used to uncover alluvial deposits.

Where Is Placer Mining Used Today?

Today, placer mining continues to uncover finer material and gold placer deposits.

Alongside gold miners in Alaska, Yukon, and British Columbia, places like Sri Lanka and Myanmar, placer miners also discover valuable minerals besides gold deposits like diamonds, gems, and platinum.

How Does Placer Mining Work?

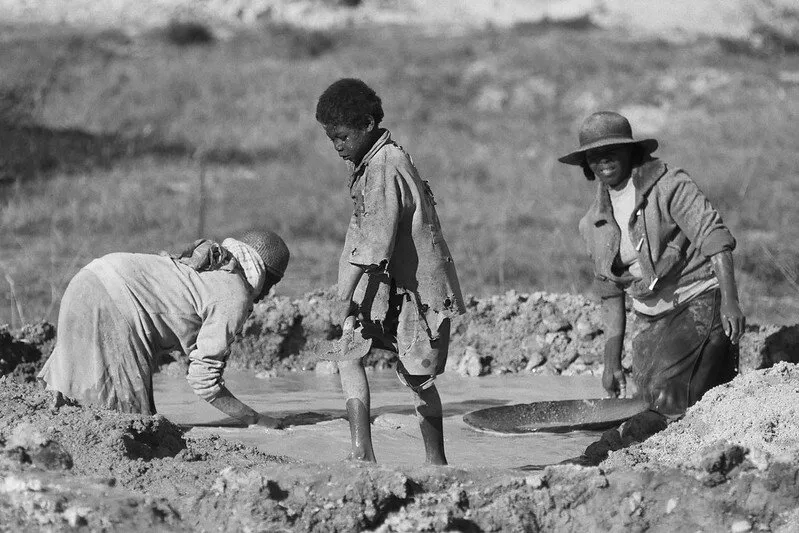

Many miners use various placer mining techniques. The most straightforward mining operation is gold panning.

Miners would use a prospector's pan and swirl a union of gravel, sand, and water so that lighter material could spill out.

Since gold weighs more than rock or sand, the heavier gold would remain while the other material spills out.

To start the process, miners must locate creek drainage that has transferred gold dust, nuggets, particles, and flakes deposited inside creek sediment layers.

Prospectors would use their gold pan to test the surfaces or dig above the bedrock where most placer gold particles would collect.

Then, the miners would follow horizontal tunnels known as drift mining to locate gold-bearing gravel.

These placer mines and tunnels were constructed the most in winter as the frozen ground wouldn't melt and collapse on the workers.

However, even with these precautions, using this placer miner technique to uncover golden placer ore was very dangerous.

Thankfully, workers use other mining strategies today, with panning mostly staying in the past.

Today, panning is hardly ever used for profit since even a skilled worker can only expect to process around a cubic yard of gold ore every ten hours. Better methods exist, especially on an industrial scale.

The Rocker Method— A Step up from the Gold Pan

Also known as a cradle, a rocker processes a greater volume than your traditional pan.

However, its production is still limited, and miners typically only use this method to process three or four yards of gravel daily.

The rocker is also portable and requires fewer building materials than sluice boxes.

The box sits upon rockers, where it separates the gold deposits. Workers commonly referred to this practice as "rocking the golden baby."

Miners used this method throughout the start of the North American golden rush frenzy, but like the pan, rockers quickly fell out of fashion.

Sluice Boxes— For Larger Scale Operations

Ground sluice boxes used the same principle as rockers but on a much larger scale.

A sluice box consists of barriers called riffles along the bottom that trap heavy placer gold deposits and other minerals as water runs over the device.

This method pairs well with excavation instruments like shovels.

While a sluice box can handle more enormous volumes of material than other methods, sometimes overall efficiency becomes a trade-off.

Conventionally, sluice boxes often recover heavy minerals at only 40% of how much actual material they process.

Like rockers and pans, sluice boxes were used the most during the gold rushes in North America, primarily for large operations, like scooping thousands of gravel every day.

However, since workers often looked in a gold-bearing stream bed, streams started depleting.

To combat this, the industry developed variants for the sluice box, such as the grizzly. The grizzly consists of parallel bars positioned at a 45-degree angle, sitting over the primary sluice box.

Another variant was undercurrent sluice boxes, consisting of additional auxiliary boxes. After undergoing initial filtration from waste material, it travels back through the primary sluice box to undergo filtration once more.

Many workers would use both the grizzly and undercurrent variants in tandem.

Dry Washing — When There Isn't a Water Supply

Workers will use a water and mechanical action for miner ore and a placer deposit when there's a water supply.

When gold emerges into a stream bed by a stream flow, golden rich bench deposits form. Even today, workers focus their actions on bench deposits.

However, workers must use other techniques when dealing with frozen ground or an arid climate with poor ground, as stream placers or placer deposits don't exist. One alternative method is called the Mexican dry wash.

This method utilizes gravel placed upon a riffle board with bellows sitting below. Typically, workers can process one and a half to four cubic yards of gravel daily with an efficiency rate of 80%.

Spanish miners often used a dry washing method called "winnowing." Winnowing only required a worker to use a blanket alongside a box composed of a box sitting on the bottom

. The material first filters throughout the box so that only finer material deposits on top of the blanket.

The worker then uses the blanket to fling the material into the air so that the wind blows away the lighter material. This process results in only leaving behind gold.

Using a Trommel

A trommel consists of a slightly inclined metal tube that rotates. In some cases, manufacturers attach lifter bars as bolted angle iron to the metal tube.

Mined ore feeds through the elevated portion of the trommel, where pressurized water frees essential minerals from the solid ore.

This mineral-filled ore then transfers through the screen, where it breaks down into jigs and sluices.

Advantages of Placer Mining

Placer mining has a few advantages that make it a better alternative to methods like surface mining.

Although this type of mining can potentially damage watersheds and impact fish health, it is a more environmentally friendly method than surface mining.

This is due to sediment returning to the water after extracting minerals and following a placer deposit.

This mining also uses large metal densities like gold, causing them to sink quickly due to moving water.

While the fundamentals of this mining haven't changed much, more effective methods exist today.

Besides placer deposits of gold, workers also use placer mining methods for materials like gemstones.

Learn More About Placer Deposits and Mining Today

Placer mining has a rich history, and many areas still use it today, including all over Alaska. If you want to learn more about its modern uses or other mining techniques, our team at An Underground Miner can help.

Join our Facebook group to enjoy discussions and memes.

This article was written by An Underground Miner