LHD's are one of the most essential pieces of machinery in the underground mining industry.

These machines also happen to be some of the most powerful heavy-duty equipment in the world, designed for maximum performance and efficiency.

The past few decades have seen an increase in the implementation of new technology in these machines in the push for a greener future.

Let us take a closer look at LHDs, their different types, and what makes an LHD the beasts of the underground mining world that they are.

Introduction to LHDs

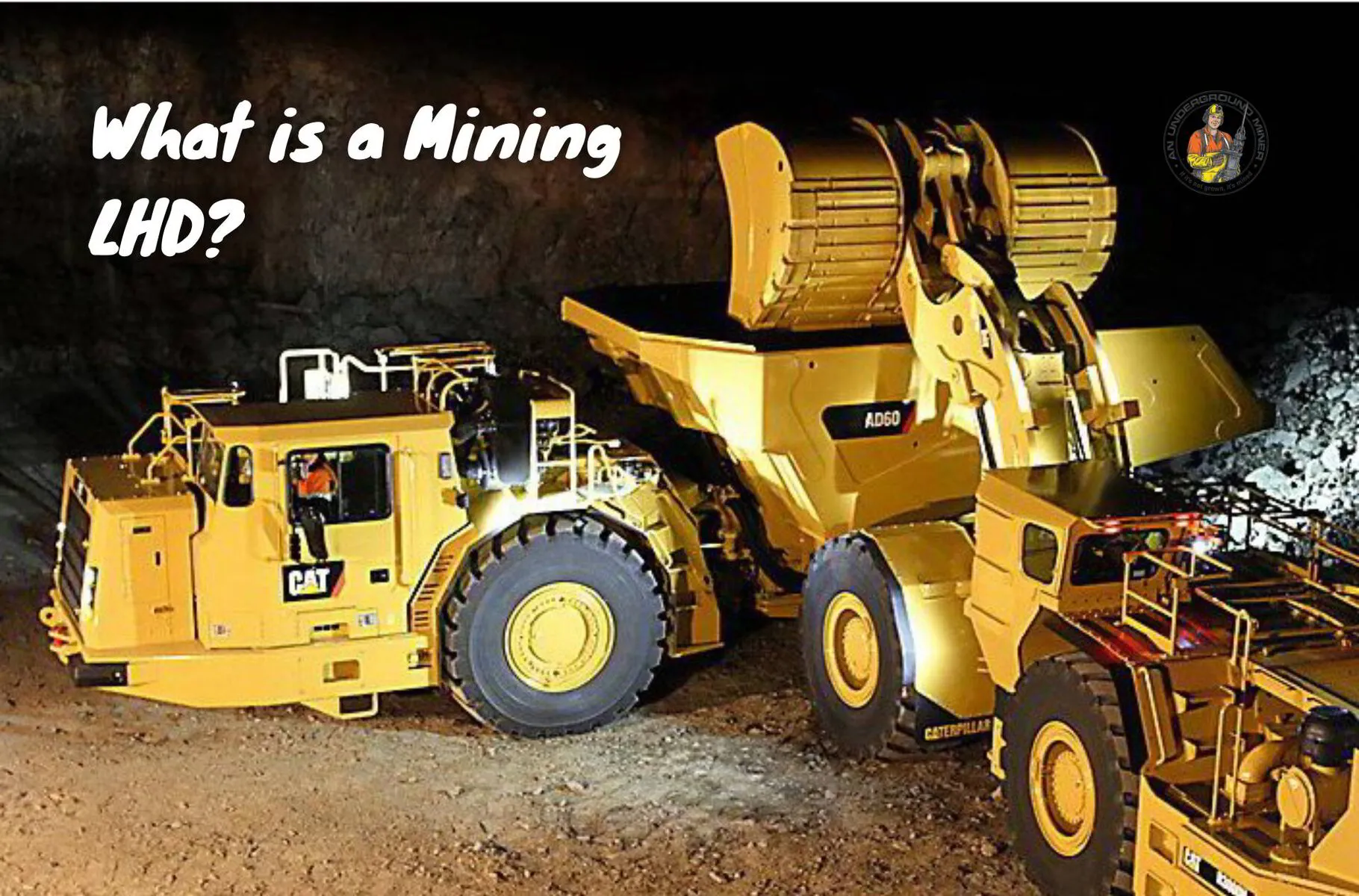

LHD or "Load Haul & Dump" machines are loaders that function similarly to the conventional front-end loaders.

These loaders are popular in underground mining operations where hard rock and other materials can be safely loaded and hauled between different sites of the operation.

LHD's are productivity-oriented and used in more than 75 percent of the world's underground metal mines.

Although Load-Haul-Dump machines have slower travel speeds than the conventional front-end loaders, they offer up to 50 percent enhanced loading capacity in a compact form factor compared to their conventional counterparts.

LHDs also offer better emissions, thanks to their smaller and more robust engines.

Construction Details

LHDs have a smaller footprint with a longer and narrower profile as compared to other front-end loaders.

It ensures perfect adaptability to all working environments, including small to large-sized tunnels and stopes, etc.

Although the machine's maneuverability is lowered due to the longer and narrower profile of the machine, it helps immensely in making the machine capable of loading more material.

The increased loading capacity of LHDs makes them a highly desirable choice for underground mining operations.

Productivity

LHDs offer enhanced work cycle times as compared to their conventional counterparts.

The smoother operation combined with a better traction system boosts productivity while reducing operation and maintenance costs.

The smaller engine in the relatively compact form factor of an LHD offers reduced emissions and heat load with faster acceleration and decreased fuel consumption.

These features and more make the LHDs productivity-oriented machines that offer excellent performance in all working conditions.

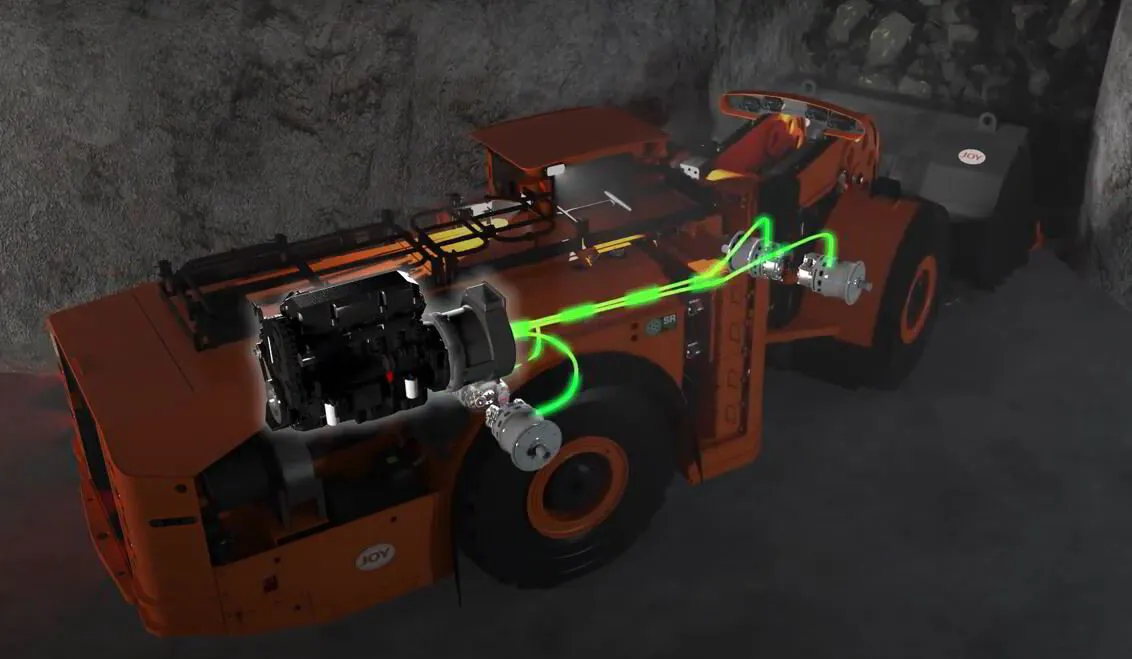

In addition to the productivity features built into most LHDs, some manufacturers like Komatsu offer additional features like the SR Hybrid Drive.

The Switched Reluctance Hybrid Drive system is designed to capture and reuse braking energy for higher fuel efficiency, shorter cycle times, and industry-leading acceleration.

Safety Considerations

Most LHDs feature a suite of enhanced safety features, including redundant/ failsafe braking system, emergency stop system, ROPS/FOPS (Rollover Protection Structure/Falling Object Protection Structure) certification for the operator's cabin, etc.

All platforms, steps, handrails, and stairs are designed keeping operator safety in mind. LHDs also offer better suspension that leads to lesser vibration in rocky areas and smoother operation in harsh work environments.

Reliability

The rugged steel frame of this equipment offers protection from wear and impact caused by tougher working environments.

All LHDs are built to withstand the harshest of working conditions in underground mining environments.

The machines come equipped with advanced hydraulic systems with piston pumps that offer cooler operation and prolonged life.

Most LHDs also feature a central automatic lubrication system. It keeps the critical joints of these machines well-lubricated for more extended operations.

It reduces the need for regular maintenance that might otherwise interrupt the flow of operations.

Payload Capacity

LHDs are available in a wide range of sizes, offering different payload capacities, generally ranging from 6,000 to 22,000 lbs. (2,700 to 10,000 kg) and even up to a whopping 55,000 lbs. (25,000 kg).

Different manufacturers offer different bucket options to suit the range and requirements of the underground mining operations.

The bucket sizes range from 1 to 13 cubic yards (0.8 to 10 cubic meters), and the bucket height varies between 6 and 8.2 feet (1.8 and 2.5 meters).

The machines vary significantly in size, offering solutions for all types of underground mining conditions.

Operator Cabins

Over the past few decades, operator comfort and safety have significantly improved.

Most operator cabins featured in LHDs from some of the industry's best manufacturers offer a suite of comfort and safety features that assist in streamlining operations and increasing productivity.

The smart displays with integrated diagnostics and real-time operation metrics provide valuable insight into the machine's functioning.

Ergonomic controls with optional cabin features like air-suspended seats offer comfort during long operation hours.

Automation

LHDs also feature advanced automated controls that allow the operators to perform challenging tasks with a simple button press.

The simplified controls allow the operators to focus on the tasks at hand, allowing for greater productivity and smooth operation.

Different manufacturers offer different automation and intelligent controls to make the load cycles faster and more efficient.

LHDs are also available with remote controls. These controls help operate the LHDs in challenging work environments where loose rock may present a falling object danger.

In such conditions, the automated controls offer a safer mode of operation than traditional LHD with human operators.

Fuel-Based & Hybrid LHDs

While the conventional LHDs are fuel-based and dependent on diesel fuel for their operation, there has been an increasing shift towards hybrid modes of operation in recent years.

The hybrid LHD can operate both on diesel fuel and battery or electrical power.

The hybrid model of operation consumes less fuel, leading to lower emissions and a smaller carbon footprint than a conventional LHD.

Additionally, the lower emissions are accompanied by lower heat production, thereby decreasing the need and cost of ventilation.

Hybrid power is quickly becoming the industry standard due to its positive impact on the environment and a desirable combination of lower fuel consumption and higher efficiency.

Most electrical or battery-powered LHDs offer smoother operation with lower long-term costs than their fuel-operated counterparts.

LHD units equipped with electric motors operate between 75 and 150 horsepower with a medium voltage of 380 to 550 volts.

Conclusion

Hopefully, our article has helped you better understand what an LHD is and how it fits into the underground mining cycle.

The pace of technological change in mining and the global requirement for materials has put a lot of emphasis on productivity in the mining industry.

New mining equipment such as hybrid LHDs with increasing levels of automation will see more significance in the near future.

So, what's next?

Stay tuned to this blog and our Facebook group to learn more about mining.

Our Facebook group, An Underground Miner, is a funny and informative group of miners and mining enthusiasts. To be part of our ongoing conversation, all you have to do is join our group today!

This article was written by An Underground Miner